Automated Dependency Mapping

Next-Generation System Risk Intelligence.

Automated Dependency Mapping (ADM) in the MADE platform transforms how failure behavior is understood in complex systems. Instead of relying on manual definitions or simplified diagrams, ADM automatically generates interdependent failure pathways, linking functional and physical failures through dynamic risk simulations. As the analytical backbone of the Digital Risk Twin (DRT), ADM provides a high-fidelity view of system vulnerabilities and cascading effects, tracing each failure from cause to end effect, offering insights beyond traditional RAMS methods which can only identify Local, Next and End effects.

Know Your System Better

See What Others Can't - MADE Maps Every Step of Failure

Where Dependency Mapping Delivers Advanatges

Turning Complex Failure Chains into Actionable Intelligence

Improves Risk Visibility

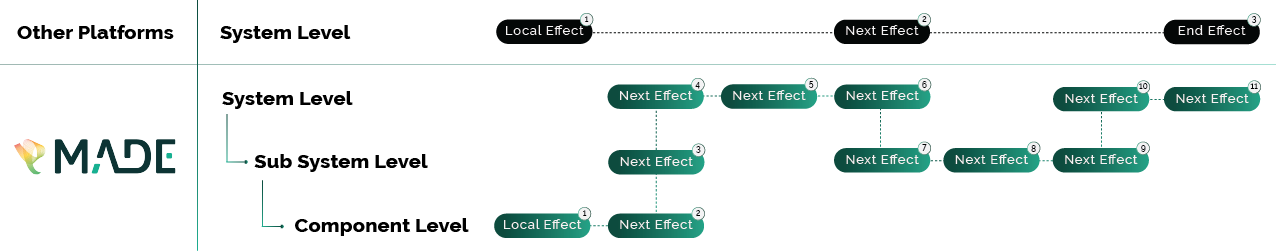

Going beyond standard Local, Next & End Effect, MADE's ADM visually displays every step of a failure.

Improves Traceability

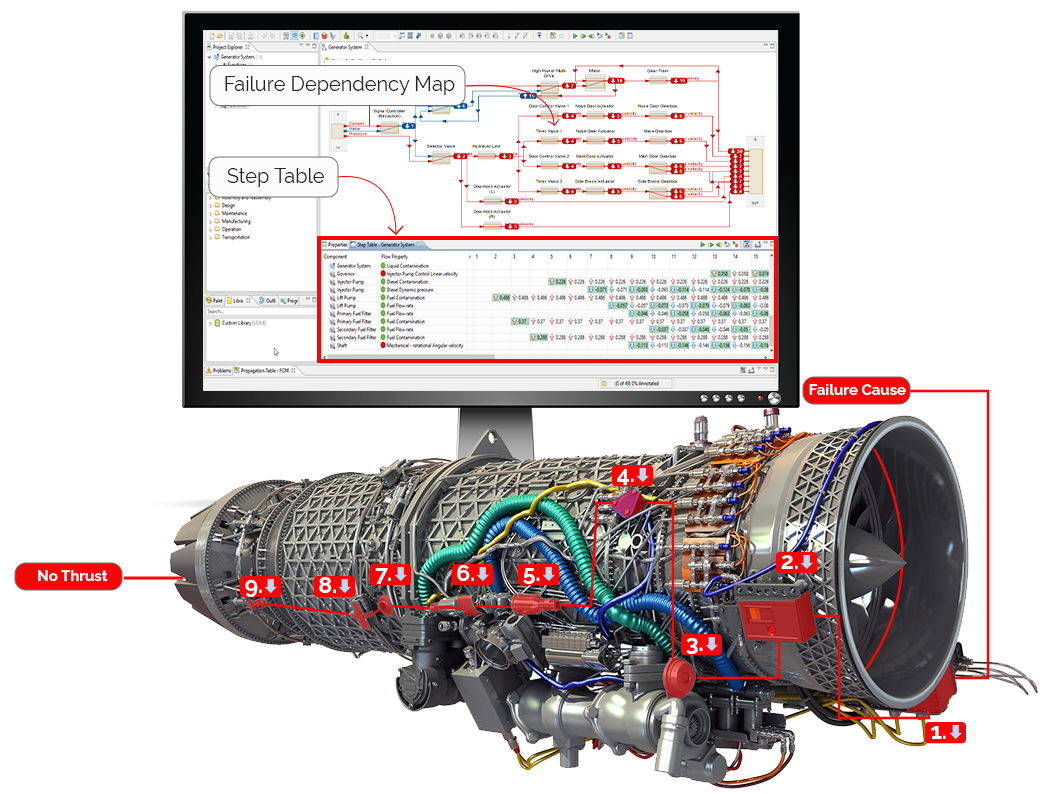

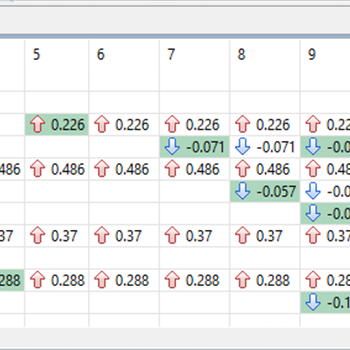

Once every step in a failure propogation is identified a step table is available so you can trace every failure to its cause.

Failure Visualization

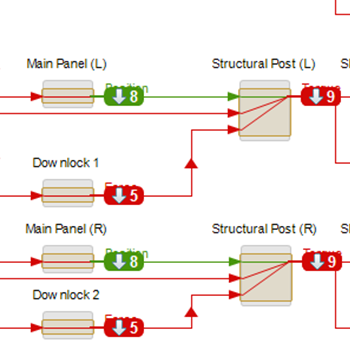

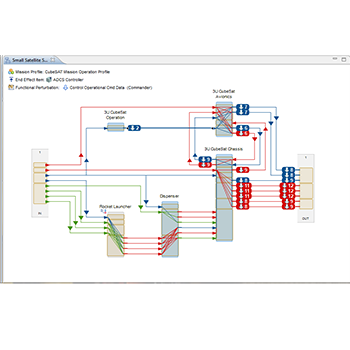

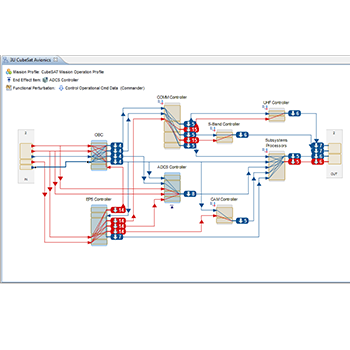

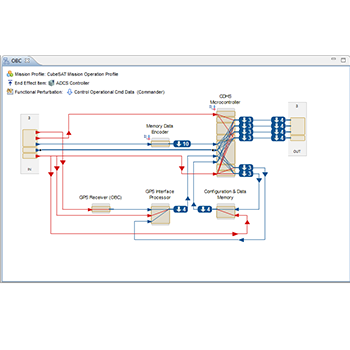

The ADM process visually displays (maps) the failure path across the Digital Risk twin in real-time.

Faster Failure Analysis

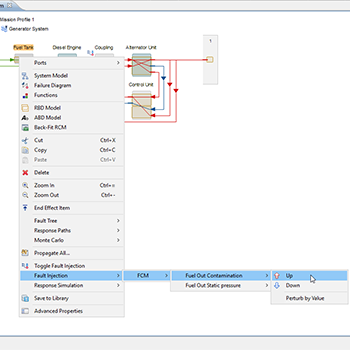

The automated mapping is driven by the functionlity and rules created in the Digital Risk Twin which can be generated through a single click.

Future-proofs Process

Domain knolwedged capture embeds failure analysis into models, which can be reused across programs, reducing learning curves and errors in future projects.

improve Design Optimization

Reveal hidden vulnerabilites, better support risk trade-offs and improve mitigation strategies becuase of better undwerstanding of intervention points.

Reduce Human Error

Failure propogation is generated autonomosly from the Digital Risk Twin, reducing assessment errors otherwise injected through manual creation of failure insights.

Better Team Collaboration

With the failure knowledge captured and centralized in a Digital Risk Twin teams in projects are drawing on the same source of data.

Design Iteration Ready

Your team can easily and efficiently produce analysis to assess design iteration impacts without a lengthy manual process.

Unlocking Digital RAMS

Turning Complex Failure Chains into Actionable Intelligence

From Function to Root Cause, Mapped Automatically, see how MADE transforms complex engineering models into actionable insight. Failure pathways are traced instantly, showing how physical faults impact system-wide functionality. This is automated dependency mapping visualized, validated, and ready for decision-making.

| Feature | MADE Automated Dependency Mapping | Traditional Methods |

|---|---|---|

| Dependency Identification | Auto-generated from system model | Manual, error-prone mapping |

| High Fidelity Failure Path | Every step in a failure is identified, visually | Local, Next & End effect only |

| Failure Propagation | Real-time cascading effects simulation | Static diagrams, no simulation |

| Standards Support | ARP4761A, FMEA, MPD | Partial or non-compliant outputs |

| System Linkage | Connects logical and physical models | Disconnected or siloed models |

| Mission & Environment | Built-in profile & loading effects | Often ignored or approximated |

| Change Impact | Auto-propagated across the model | Manual updates required |

| Traceability | Integrated in Digital Risk Twin | Limited or non-existent |

| Scalability | Supports large systems with reusable libraries | Challenging, high effort to maintain |

| Efficiency | Fast, repeatable workflows | Time-consuming and inconsistent |

Key Features of MADE's Dependency Mapping

Clear, Connected Views of Failure Pathways at Every System Level

Failure Injection

Automated Dependency Map

Failure Step Table

System Level Failures

Sub-system Failures

SubSub-system Level Failures

What Users Say

“Going from a Local, Next and End effect in our failure analysis to MADE's detailed, high-fidelity Automated Dependency Mapping was incredibly insightful.”

“Understanding failures across multiple levels of indenture in a system from component to sub-system and system is made that much easier with MADE's Automated Dependency Mapping.”

Start Your MADE Software Journey Today

Let’s explore how the MADE Realibility Software can transform your engineering processes

Whether you have a specific challenge in mind or just want to learn more, we’re here to help. Fill out the form below and one of our experts will get back to you shortly with insights tailored to your needs.